The Polo: 4 Steps for 1 Shirt

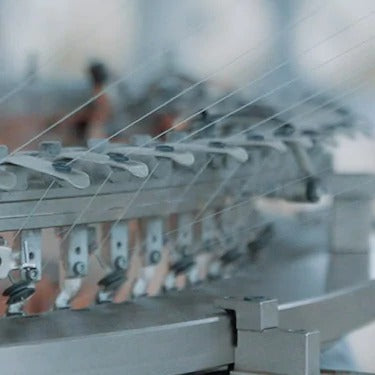

The knitting

The dyeing

The crocodile’s seal

The assembly

Material Evidence

Petit Piqué

Diamond Weave Taffeta

Troyes, France in three key numbers

160 kilometres, the distance between the French knitwear capital and Paris. It’s not surprising then, that this is where René Lacoste established a manufacturing base to make the first polos.

500 people, the number of employees in the Troyes factories. There are various jobs to do, from pattern makers to garment-makers and knitting or dyeing machine operators. Coordinated effort from all of these experts results in your Lacoste polo.

40 minutes, the average length of time required by a garment-maker to assemble your polo like a puzzle.